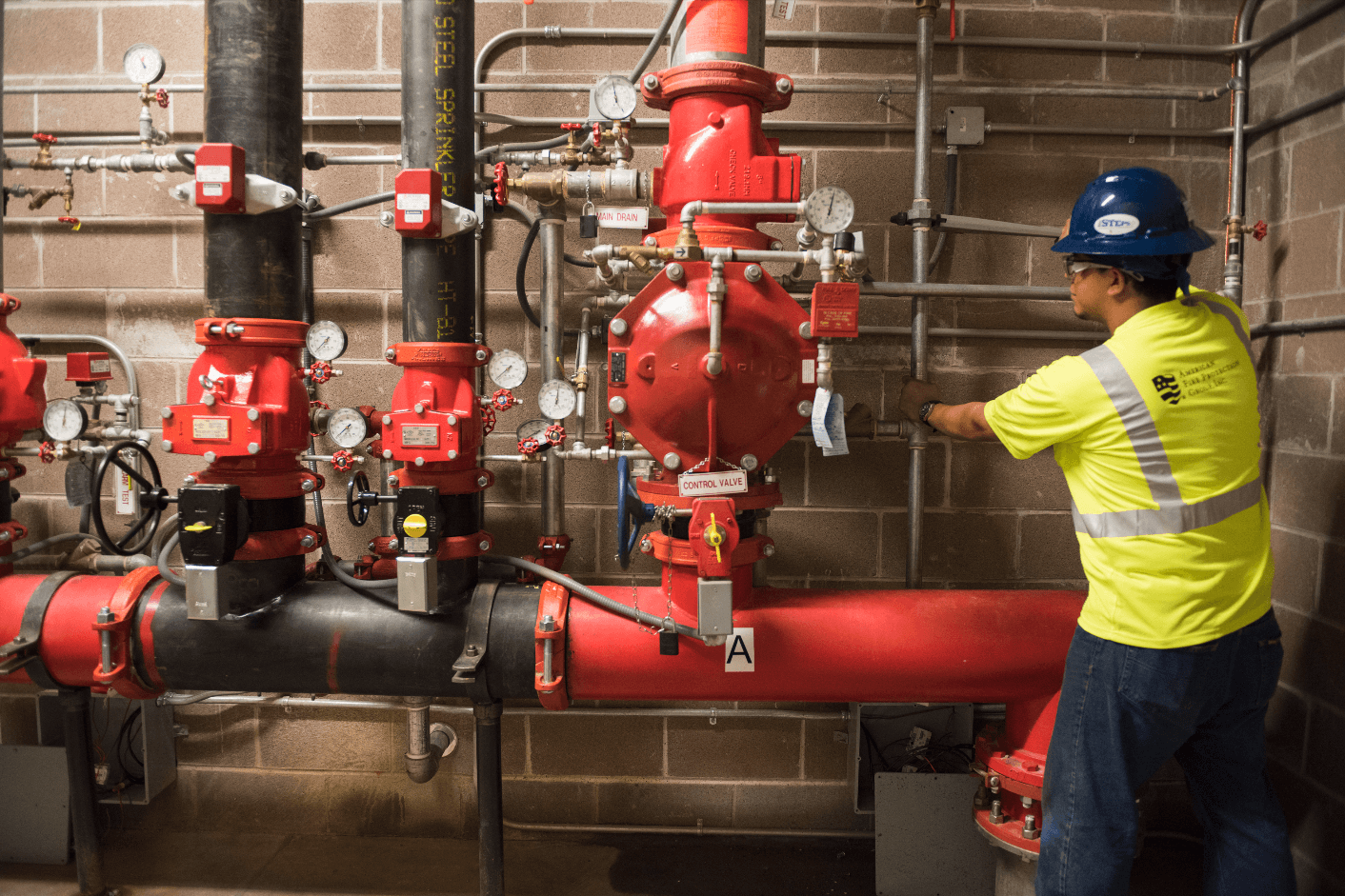

Our experienced technicians can handle fire protection-related emergencies of any kind and magnitude. The applications are suitable for all types of facilities including data centers, hospitals, stadiums, warehouses or any other site where a wet, dry, or pre-action system exists.

We also offer corrosion control in fire sprinkler piping by way of nitrogen. Our design staff utilizes advanced 3D CAD design programs which enable us to coordinate fire sprinkler design with other trades involved with any of our projects. In addition to performing the required inspection and maintenance, we can extend the life of the system, improve its reliability and reduce the overall cost of maintenance. We will work hand in hand with you and design a program that will meet your needs. Inspection and maintenance of sprinklers are required on a monthly, quarterly, semiannual, annual, and five-year basis.

With our fire sprinkler system inspection and PM services, you can be confident that your systems are prepared to protect the lives of the building’s occupants, protect your property, and pass your local fire protection jurisdiction requirements. Our team’s combined 200+ years of industry experience allows us to offer design, installation, preventative maintenance (PM), and emergency services.

Well maintained and functioning fire sprinkler systems are an integral part of a company’s overall fire safety plan. A repeat presentation will be given at MODEX 2018, held April 9-12 at the Georgia World Congress Center in Atlanta.Sprinklers save lives. The presentation and accompanying audio recording are available here. Want to learn more about fire suppression systems and their impact on rack? RMI member DACS presented “Warehouse Fire Sprinkler Codes and Impact on Storage Racks” in an on-floor seminar at ProMat 2017. Some of these are required to create smoke and heat barriers, or for keeping required flue spaces open. Key factors include the type of items being stored, the density of the storage rack, the product storage height, and the overall building height.īecause adding a fire suppression system impacts rack structure design and geometry, it is important to engage an engineer who is also familiar with the products that are available.

#Warehouse fire sprinkler system design professional#

FM Global Property Loss Prevention Data Sheets, providing engineering standards to reduce the potential for firesīased on each unique situation, the professional designer or engineer will ascertain which rules need to be followed when developing a facility’s fire suppression system.

#Warehouse fire sprinkler system design code#

The International Code Council (ICC) International Fire Code (IFC), regulations to safeguard life and property from fires and explosion hazards.NFPA 13, a design standard for the installation of sprinkler systems.To ensure that a facility’s sprinkler system and racking are properly designed and will work together effectively, it is critical to work with a qualified, fire protection professional familiar with the pertinent warehouse fire sprinkler design and building codes, including: That’s because the addition of wet pipe sprinkler systems into a warehouse structure-supported by a proper in-rack design that permits the water to flow through the storage system in the most optimal manner-is one of the most effective ways to reduce potential damage and deaths. To support the development of better prevention measures, RMI participates in the NFPA committee tasked with the creation and revision of national standards specific to the safe design of sprinkler systems. The leading causes of warehouse fires are arson or electrical.These fires result in an annual average of $155 million in direct property damage, and the death or injury of 22 individuals.fire departments respond to an estimated average of 1,210 fires in warehouses annually. According to statistics from the National Fire Protection Association (NFPA):

0 kommentar(er)

0 kommentar(er)